Pump control systems optimize fluid handling, ensuring peak performance with sensors and actuators. These systems uphold operational integrity, minimizing downtime by adjusting pump operations in real-time. Understanding their intricate components reveals their pivotal role in maximizing efficiency across industries. Discover What Are Pump Control Systems? and How They Boost Efficiency in Fluid Handling!

Key Takeaways

- Regulate flow, pressure, and operation using sensors and controllers.

- Ensure peak efficiency and performance of pumps.

- Employ actuators to adjust pump functions as needed.

- Found in industrial, commercial, and residential settings.

- Monitor and optimize pump performance for energy savings.

Understanding Pump Control Systems

To understand the functionality and significance of pump control systems, it is essential to explore the intricate mechanisms that govern their operation. Pump control systems are designed to regulate the flow, pressure, and operation of pumps in various applications. These systems utilize sensors, controllers, and actuators to monitor and adjust pump performance, ensuring peak operation and efficiency in industrial, commercial, and residential settings.

Components of Pump Control Systems

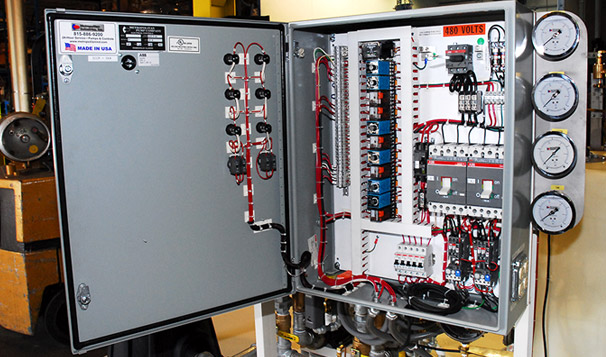

Understanding the complex mechanisms of pump control systems involves a detailed examination of the pivotal components that work together to regulate pump performance effectively. These components typically include sensors for measuring flow rates and pressure, controllers for interpreting data and making adjustments, and actuators for physically altering pump operations. Additionally, communication interfaces, power supplies, and safety mechanisms play vital roles in ensuring the system functions reliably and efficiently.

Benefits of Pump Control Systems

Pump control systems offer a multitude of advantages in optimizing pump performance and operational efficiency. These systems enhance energy efficiency by adjusting pump speed to match demand, reducing energy consumption and costs. Additionally, they help prevent pump damage and extend equipment lifespan by controlling pressure levels and ensuring proper system operation. Overall, pump control systems contribute to improved reliability, reduced maintenance, and enhanced overall system performance.

Common Applications of Pump Control Systems

Enhancing water distribution networks, controlling wastewater treatment processes, and regulating HVAC systems are among the common applications of pump control systems. These systems play an essential role in ensuring efficient water flow, maintaining water quality, and optimizing energy usage in various industrial and commercial settings. By automating pump operations based on demand and system conditions, pump control systems contribute to overall operational efficiency and cost savings.

Maintenance Tips for Pump Control Systems

To secure the best performance and longevity of pump control systems, regular and thorough maintenance is essential.

1. Inspect Regularly: Check for leaks, unusual noises, and any signs of wear.

2. Clean Filters: Secure filters are clean to prevent clogs and maintain efficiency.

3. Monitor Fluid Levels: Keep an eye on fluid levels and top up as needed.

4. Calibrate Sensors: Periodically calibrate sensors to secure accurate readings.

Conclusion

To sum up, pump control systems play a vital role in regulating pump operations across various industries by monitoring and adjusting flow rates, pressure levels, and performance. With their components and functions designed to enhance efficiency and reliability, these systems contribute greatly to optimizing system performance and extending equipment lifespan. By understanding their benefits, applications, and maintenance requirements, users can guarantee the effective operation of pump control systems in their respective settings.